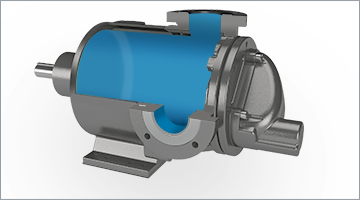

Take your pump performance to the next level with Blackmer seal-less E Series Gear Pumps. Innovative, durable and environmentally friendly, E Series Gear Pumps have been engineered to be a cut above the competition thanks to a revolutionary design with a patented between-the-bearing support system. This one-of-a-kind design eliminates leaks and reduces mechanical wear, helping increase the safety of site personnel and the environment. Material of construction options of ductile iron, carbon steel and stainless steel allow for a wide range of chemical compatibility. In addition, no other magnetically coupled pump offers a lower upfront cost, lower total cost of ownership or more reliability than the E Series Gear Pump.

Available Materials

- Ductile Iron

- Carbon Steel

- Stainless Steel

Max Temperature

- 500°F (260°C)

Capacity

- 15 gpm to 500 gpm (3.4 m³/h to 113.6 m³/h)

Max Pressure

- Ductile Iron – 200 psi (13.8 bar)

- Carbon Steel – 200 psi (13.8 bar)

- Stainless Steel – 150 psi (10.3 bar)

Features

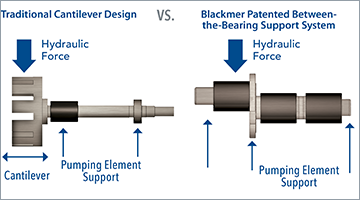

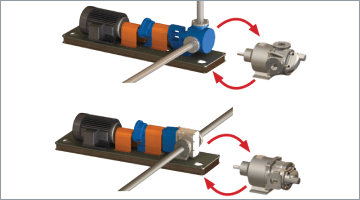

Between-the-Bearing Support System

Eliminates the damaging effects of cantilevered loads that are present in competitor internal gear pumps, maximizing rotor, idler and bushing life.

One Fluid Chamber Design

Greatly improves fluid circulation through the magnetic coupling, resulting in lower operating temperatures, longer magnet life, and more effective cleaning and flushing processes.

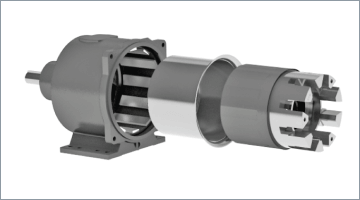

High-Torque and Compact Magnetic Coupling

High-strength magnetic couplings are standard to allow for more operational flexibility, with inner magnets mounted directly to the rotor for an extremely compact design.

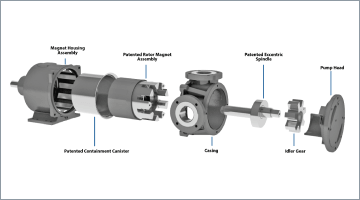

Simple Design

The need for only seven primary components improves reliability and reduces system complexity while easing maintenance and repair.

Competitor Pump Interchangeability

Interchangeable with up to 95% of the packed, mechanically sealed and seal-less magnetic gear pumps in use today, with no need for piping, driver, baseplate or coupling modifications.

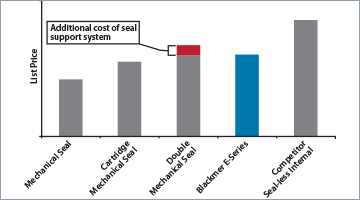

Affordable Upfront Solution

Due to the simple, seven primary-component part design, E Series Magnetic Drive Gear Pumps have a much lower investment cost than competitors’ magnetic gear pumps.

Specifications and Performance

| Model | Ductile Iron Gear Pump Port Sizes | Carbon Steel Gear Pump Port Sizes¹ | Stainless Steel Gear Pump Port Sizes¹ | |||

|---|---|---|---|---|---|---|

| Threaded | Flanged | Threaded | Flanged | Threaded | Flanged | |

| E1-2 E1-4 | N/A | N/A | 1-1/2" NPT 1-1/2" BSPT | 1-1/2" ANSI 2" ANSI DN40 | 1-1/2" NPT 1-1/2" BSPT | 1-1/2" ANSI 2" ANSI DN40 |

| E1-24 E1-32 | 2" NPT 2" BSPT | 2" ANSI 2" ANSI 180° | 2" NPT 2" BSPT | 2" ANSI 2" ANSI 180° 3" ANSI | 2" NPT 2" BSPT | 2" ANSI 2" ANSI 180° 3" ANSI DN50 |

| E1-55 E1-69 E1-82 | N/A | 3" ANSI 4" ANSI | N/A | 3" ANSI 4" ANSI DN80 | N/A | 3" ANSI 3" ANSI 180° 4" ANSI DN80 |

| E1-133 | N/A | 4" ANSI² | N/A | 4" ANSI 4" ANSI 180°* 6" ANSI 180°* | N/A | 4" ANSI |

| E1-222 | N/A | 6" ANSI² 180° | N/A | 6" ANSI 180° | N/A | 6" ANSI 180° |

(1) Flanged connections meet Class 150# ANSI

(2) Flanged connections meet Class 125# ANSI

* Flanged connection options to meet Class 150# or 300# ANSI

Note: All port orientations 90° unless specifically noted 180°

Note: All E Series ANSI flanges are "raised-face" (RF), with the exception of E1-133/222 models which are "flat-face" (FF)

| Model | Ductile Iron / Carbon Steel Gear Pumps | Stainless Steel Gear Pumps | ||

|---|---|---|---|---|

| RPM | GPM (m³/h) | RPM | GPM (m³/h) | |

| E1-2 | 1,750 | 15 (3.4) | 1,150 | 10 (2.3) |

| E1-4 | 1,750 | 30 (6.8) | 1,150 | 20 (4.5) |

| E1-24 | 780 | 75 (17.0) | 640 | 55 (12.5) |

| E1-32 | 780 | 100 (22.7) | 640 | 80 (18.2) |

| E1-55 | 640 | 135 (30.7) | 520 | 110 (25.0) |

| E1-69 | 640 | 170 (38.6) | 520 | 140 (31.8) |

| E1-82 | 640 | 200 (45.4) | 520 | 160 (36.3) |

| E1-133 | 520 | 300 (68.1) | 520 | 300 (68.1) |

| E1-222 | 520 | 500 (113.6) | 520 | 500 (113.6) |

Competitor Model Cross Reference

| Blackmer E Series | Blackmer G Series | Viking® | Tuthill® | Gorman-Rupp® |

|---|---|---|---|---|

| E1-2 | G1-2 | H | 015 | GHS 1-1/2 |

| E1-4 | G1-4 | HL | 030 | GHS 1-1/2 |

| E1-24 | G1-24 | K | 120 | GHS 2 |

| E1-32 | G1-32 | KK | 130 | GHS 2 |

| E1-55 | G1-55 | L & LQ | 200 | GHS 2-1/2, 3 |

| E1-69 | G1-69 | LL | 210 | GHS 3 |

| E1-82 | G1-82 | LS | 250 | GHS 3 |

| E1-133 | G1-133 | Q | N/A | GHS 4 |

| E1-222 | G1-222 | QS | 550 | GHS 6 |