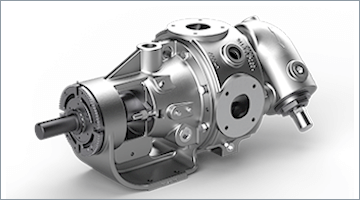

When you expect more from your current gear pump, Blackmer® G Series Internal Gear Pumps have you covered. As the high-quality, reliable alternatives to competitive models, G Series positive displacement gear pumps have the durability, flexibility and efficiency you need to safely and securely handle all your challenging fluid-handling applications. Whether it's simply time for an upgrade or you're looking for a jacketed pump to maintain process temperature and integrity during operation, replace your current gear pump worries with a durable, flexible and efficient solution that provides peace-of-mind performance backed by superior and experienced customer service and factory support.

Available Materials

- Cast Iron

- Carbon Steel

- Stainless Steel

Jacketed Option (Cast Iron Only)

- G2-55

- G2-69

- G2-82

- G2-133

- G2-222

Max Temperature

- 650°F (343°C)

Capacity

- 15 gpm to 500 gpm (3.4 m³/h to 113.6 m³/h)

Max Pressure

- Cast Iron – 200 psi (13.8 bar)

- Carbon Steel – 200 psi (13.8 bar)

- Stainless Steel – 150 psi (10.3 bar)

Features

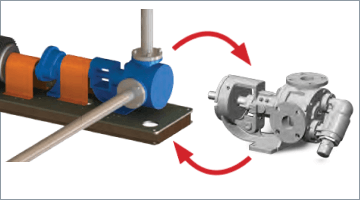

Competitor Pump Interchangeability

Interchangeable with up to 95% of the mechanically sealed, packed and seal-less internal gear pumps in use today, with no need for piping, driver, baseplate or coupling modifications. G Series Internal Gear Pumps are designed to be part-for-part replacements for many competitor pump models and are available in cast iron, carbon steel and stainless steel.

Direct Replacement Part Interchangeability

G Series parts are designed to be direct replacements for Viking® H, HL, K, KK, L, LQ, LL, LS, Q and QS models. Available in cast iron, carbon steel and stainless steel construction.

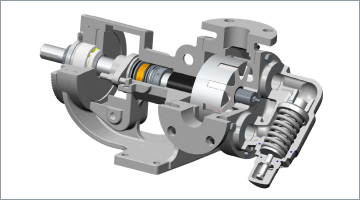

Seal Chamber with Universal Design and Heavy-Duty Oversized Bearing Housing

An oversized bracket and seal chamber allows the use of numerous sealing technologies, including packing, mechanical seals and lip seals. The large cast-iron bearing housing allows the mechanical seals to be removed without the need to take the gear pump out of service.

Jacketed Pump Options for Process Integrity

Available on G Series G2-55 - 222 cast iron models, jacketed pump components efficiently heat the seal area and pump internals to maintain process temperature and integrity during operation. Jackets allows for greater temperature control and stability, preventing the product from hardening and damaging the seal upon startup and provides faster startup than a cold pump would allow.

Specifications and Performance

| Standard Non-Jacketed (G1) | Jacketed³ (G2) | Standard Non-Jacketed (G1) | Standard Non-Jacketed (G1) | |||||

|---|---|---|---|---|---|---|---|---|

| Model | Cast Iron Port Sizes² | Cast Iron Port Sizes² | Carbon Steel Port Sizes¹ | Stainless Steel Port Sizes¹ | ||||

| Threaded | Flanged | Threaded | Flanged | Threaded | Flanged | Threaded | Flanged | |

| G1-2 G1-4 | 1-1/2" NPT | N/A | N/A | N/A | N/A | 1-1/2" ANSI | N/A | 1-1/2" ANSI |

| G1-24 G1-32 | 2" NPT | N/A | N/A | N/A | N/A | 2" ANSI | N/A | 2" ANSI |

| G1-55 / G2-55 | 2" NPT | 2-1/2" ANSI | 2" NPT | 2-1/2" ANSI | N/A | 2-1/2" ANSI | N/A | 2-1/2" ANSI |

| G1-69 / G2-69 G1-82 / G2-82 | N/A | 3" ANSI | N/A | 3" ANSI | N/A | 3" ANSI | N/A | 3" ANSI |

| G1-133 / G2-133 | N/A | 4" ANSI | N/A | 4" ANSI | N/A | 4" ANSI 4" ANSI 180°* 6" ANSI 180°* | N/A | 4" ANSI |

| G1-222 / G2-222 | N/A | 6" ANSI 180° | N/A | 6" ANSI 180° | N/A | 6" ANSI 180° | N/A | 6" ANSI 180° |

(1) Flanged connections meet Class 150# ANSI

(2) Flanged connections meet Class 125# ANSI

(3) Jacketed bracket, head, and valve available in 55-133 sizes; 90 deg ANSI case optional for 55 and 133 sizes only

* Flanged connection options to meet Class 150# or 300# ANSI

Note: All port orientations 90° unless specifically noted 180°

Note: All G Series ANSI flanges are flat-face (FF)

| Standard Non-Jacketed (G1) | Jacketed¹ (G2) | Standard Non-Jacketed (G1) | Standard Non-Jacketed (G1) | |||||

|---|---|---|---|---|---|---|---|---|

| Model | Cast Iron | Cast Iron | Carbon Steel | Stainless Steel | ||||

| RPM | GPM (m³/h) | RPM | GPM (m³/h) | RPM | GPM (m³/h) | RPM | GPM (m³/h) | |

| G1-2 | 1,750 | 15 (3.4) | N/A | N/A | 1,750 | 15 (3.4) | 1,150 | 10 (2.3) |

| G1-4 | 1,750 | 30 (6.8) | N/A | N/A | 1,750 | 30 (6.8) | 1,150 | 20 (4.5) |

| G1-24 | 780 | 75 (17.0) | N/A | N/A | 780 | 75 (17.0) | 520 | 50 (11.4) |

| G1-32 | 780 | 100 (22.7) | N/A | N/A | 780 | 100 (22.7) | 520 | 65 (14.8) |

| G1-55 / G2-55 | 640 | 135 (30.7) | 640 | 135 (30.7) | 640 | 135 (30.7) | 420 | 90 (20.4) |

| G1-69 / G2-69 | 520 | 140 (31.8) | 520 | 140 (31.8) | 520 | 140 (31.8) | 420 | 110 (25.0) |

| G1-82 / G2-82 | 640 | 200 (45.4) | 640 | 200 (45.4) | 640 | 200 (45.4) | 520 | 160 (36.3) |

| G1-133 / G2-133 | 520 | 300 (68.1) | 520 | 300 (68.1) | 520 | 300 (68.1) | 350 | 200 (45.4) |

| G1-222 / G2-222 | 520 | 500 (113.6) | 520 | 500 (113.6) | 520 | 500 (113.6) | 350 | 320 (72.7) |

Competitor Model Cross Reference

| Blackmer G Series | Blackmer E Series | Viking® | Tuthill® | Gorman-Rupp® |

|---|---|---|---|---|

| G1-2 | E1-2 | H | 15 | GHS 1-1/2 |

| G1-4 | E1-4 | HL | 30 | GHS 1-1/2 |

| G1-24 | E1-24 | K | 120 | GHS 2 |

| G1-32 | E1-32 | KK | 130 | GHS 2 |

| G1-55 / G2-55 | E1-55 | L & LQ | 200 | GHS 2-1/2, 3 |

| G1-69 / G2-69 | E1-69 | LL | 210 | GHS 3 |

| G1-82 / G2-82 | E1-82 | LS | 250 | GHS 3 |

| G1-133 / G2-133 | E1-133 | Q | N/A | GHS 4 |

| G1-222 / G2-222 | E1-222 | QS | 550 | GHS 6 |