The vaporizing and Mixing units are designed for use of propane/butane in gas supply systems intended to run on natural gas in order to ensure the uninterrupted operation of burners for various purposes while reducing the volumes of natural gas supply (the peak loads reduction function) as well as to carry out the main gas supply (the reserve or emergency gas supply function). The advantage of using the vaporizing and Mixing units is that the gas burners for propane/butane do not require adjustment.

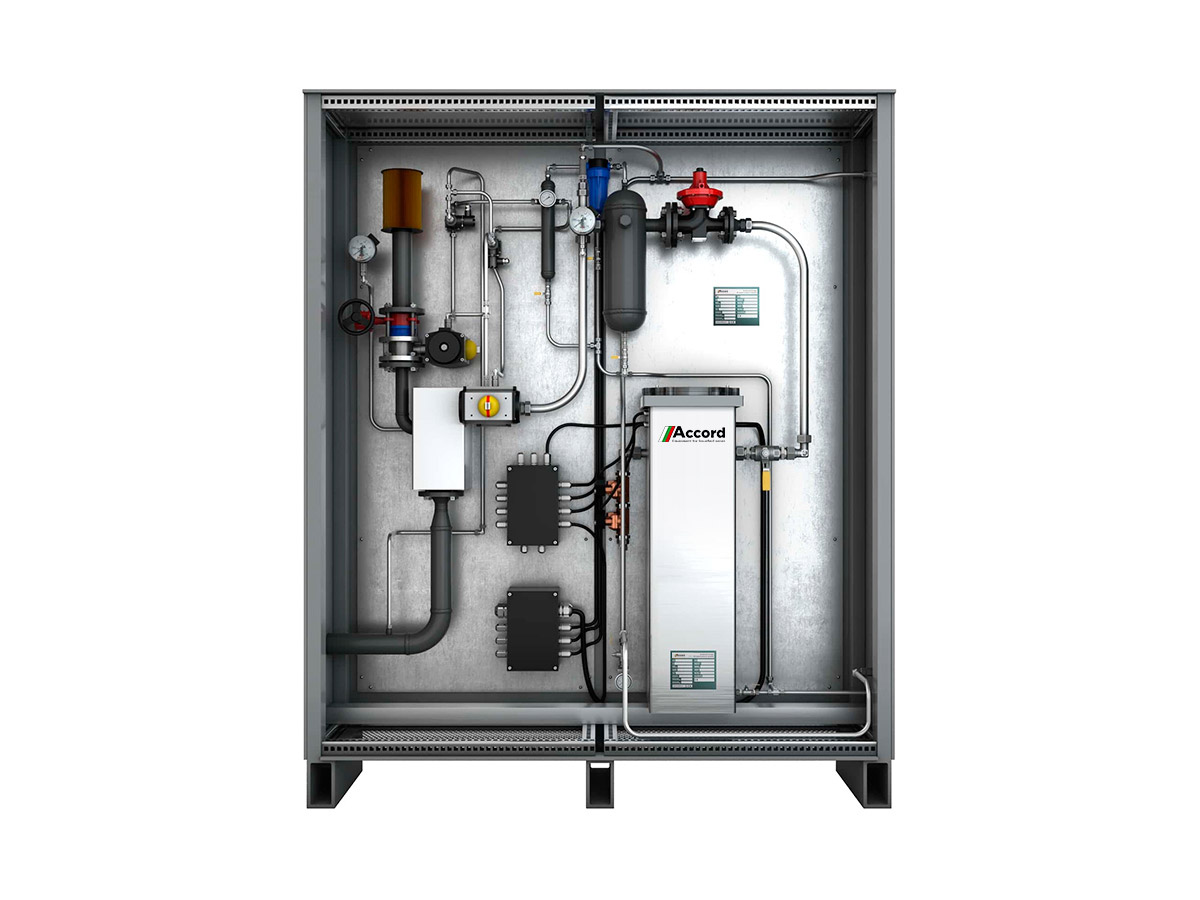

Vaporizing and Mixing Units

Our company manufactures mixing units, vaporizing and mixing units, as well as autonomous self-heating systems for liquid vaporizing units working on liquefied propane/butane. The product catalogue includes both low-pressure mixing and vaporizing-mixing units as well as high-pressure units. Our units are designed for various volumes of gas consumption: from 150 m3/hour to 9,600 m3/hour.

Advantages of vaporizing and Mixing Units

- Using the vaporizing and mixing units ensures a continuous gas supply of the facility;

- The units can operate on both external and internal sources of gas supply and be adjusted for them, depending on cost-saving advantages at a particular moment in time;

- Using the vaporizing and mixing units produced by our company makes it possible to create gas reserves for a desired period of time;

- Our company reduced the size of the vaporizing units used in the production of vaporizing-mixing systems, while maintaining their high capacity level;

- The company's manufacturing, service and storage facilities are available worldwide, which means that the equipment and spare parts can be supplied and serviced fast.

Basic Specifications of Vaporizing and Mixing Equipment

We can manufacture an vaporizing and mixing unit according to the customer's specifications with the required characteristics. However, there are ready-made solutions with standard set parameters.

Basic Specifications of Mixing Units

- The capacity of SU/ND mixing units of standard configuration varies from 150 m3/hour to 9,600 m3/hour of ready-made mixture;

- The LPG inlet pressure is from 2 to 5 bar, while the outlet pressure is up to 500 mbar (depends on the incoming pressure);

- The LPG outlet pressure: 10 °C above the dew point;

- The estimated product used: a mixture of propane/butane 60/40, 112.6 mJ/cm;

- Composition of the LPG/air mixture: 56/44%.

Basic Specifications of Vaporizing Units

- The capacity of SE vaporizing units with electric heating varies from 10 to 600 kg/hour;

- The voltage required for the operation of electric vaporizers varies from 45 kW to 360 kW;

- Liquid vaporizing units feature higher output and are more cost-saving than electric ones. They are configured to produce an LPG volume of 1,200 kg/hour to 9,600 kg/hour;

- The required water temperature is 70–90 oC;

- The rated gas/water pressure makes 25/10 bar.